TwistSeal Lid

Year

2024

Role

Designer

Overview

Redesign to standardised aluminium can construction

Resealing a beverage often means searching for a lost plastic cap, using wasteful wraps, or ending up with a stale drink. This inspired me to redesign the aluminum can itself—eliminating excess materials to reduce waste, keep drinks fresh, and create a more sustainable, clutter-free solution.

Problem Statment

The Quest of the Forgotten Lid

Have you ever needed to reseal a soda, beer, or other beverage but couldn’t find the specialized plastic cap you tucked away in some long-forgotten kitchen drawer? Left scrambling, you resort to flimsy plastic or aluminum wrap, or worse, toss the open can into the fridge uncovered, only to be greeted by a flat, stale drink the next day? I think most of us have.

This common struggle inspired me to create a solution, by redesigning the aluminum can itself to eliminate the need for those unnecessary methods and easily misplaced accessories, ensuring your drink stays fresh and your drawers clutter-free from additional dust catchers.

Key Takeaways

Plastic Lids

Plastic lids are unsustainable, contributing to waste and environmental impact, making alternative solutions necessary.

Removing Plastic

Removing a solution to a problem solely for plastic reduction is not viable without another solution taking its place.

Situational need

When on the go or at home, users may not want to finish a drink immediately but still want to preserve carbonation, this means going to fetch the plastic lid which probably is displaced in some drawer.

Design Process

Ideation

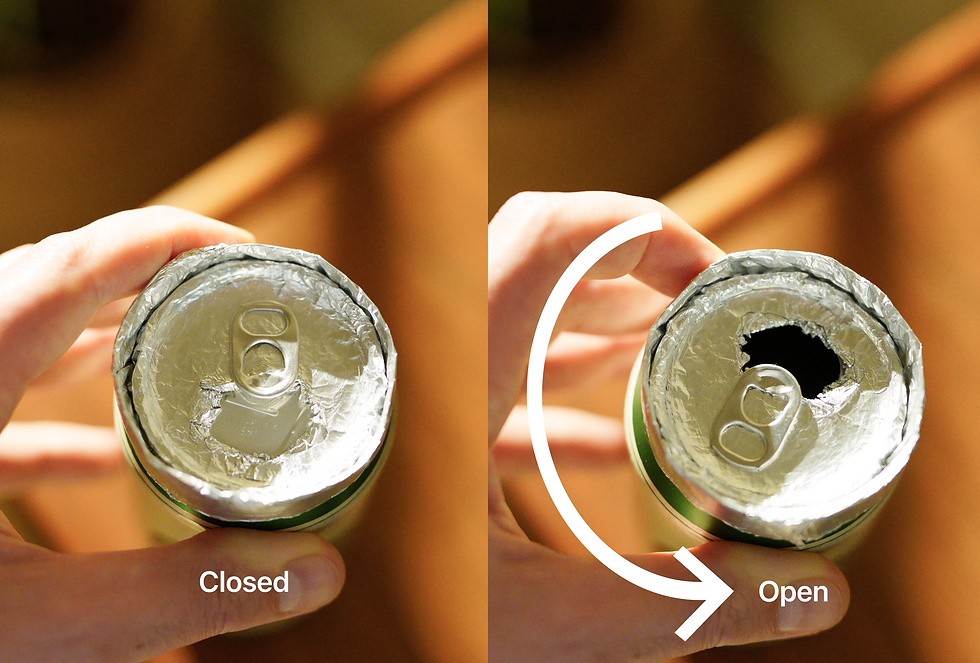

The ideation process involved sketches and bodystorming, using a can to explore the most natural and effective interaction. A clear solution emerged: a friction-based, twisting mechanism for opening and closing. Twisting right reveals the opening, while twisting left seals the can.

Experimentation

Two experiment variants were created, one with aluminium foil and another with clay. This was to explore different aspects of the design. The aluminium prototype tested functionality, look and feel, while the clay version allowed for easier pattern experimentation to improve grip.

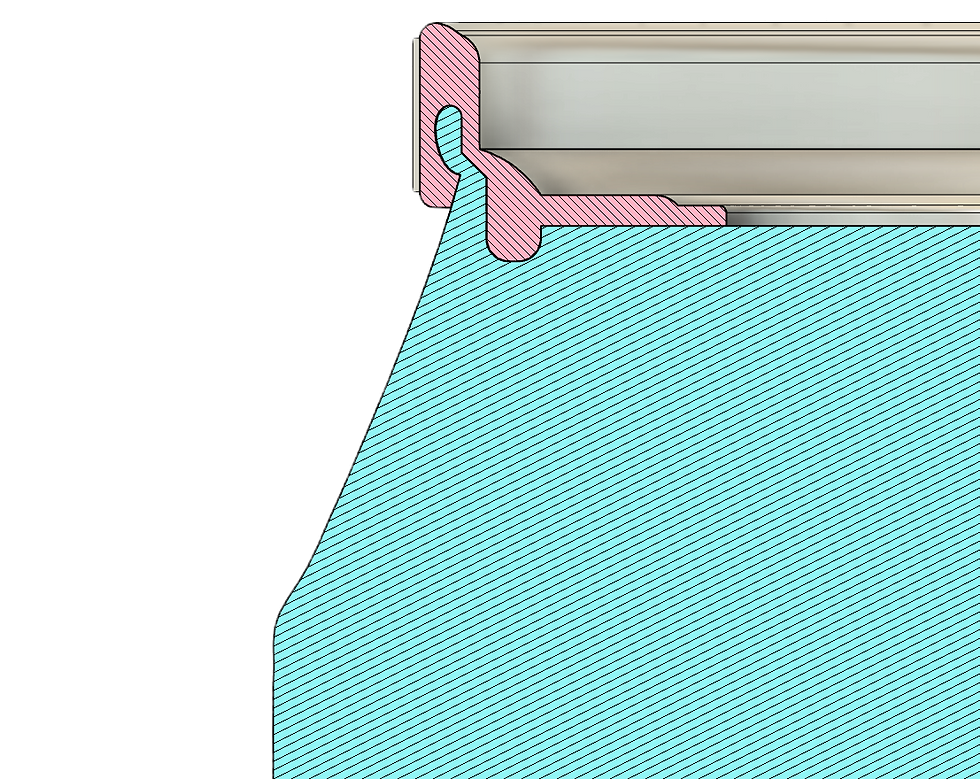

CAD Prototyping

The initial goal was to eliminate the opening tab altogether and create a single motion for both opening and sealing. However, no fully viable solution was found. Further ideation and refinements are needed to address these challenges. For now, the design retains the tab for opening while implementing a twisting motion for sealing.

Final iteration and Tests

A 3D-printed prototype was created to test functionality, ergonomics, and interaction. The twisting mechanism performed exceptionally well, but the lid didn’t fit the aluminum body due to designing for aluminum manufacturing rather than PLA. A mockup test was conducted; however, the compromised seal made it unfeasible to fairly test for leakage or carbonation retention which needs to be sorted in the next iteration.